Executive Summary: opXR is a Meta Quest 3 application that creates virtual third spaces for distributed teams while overlaying digital twin technology onto physical operations, enabling remote collaboration, real-time training, and data-driven situational awareness across manufacturing, energy, and retail environments. [Reading time: 4 minutes]

The Vision

opXR represents a fundamental reimagining of how enterprise teams interact with their operations, their data, and each other. Built for the Meta Quest 3, the platform addresses a persistent challenge in modern business: teams are increasingly distributed, yet their work remains tied to physical spaces and real-time conditions. opXR bridges this gap through three interconnected modes—virtual reality spaces for remote collaboration, mixed reality digital twins that overlay data onto physical environments, and augmented reality tools for on-site workers—all accessible through a single, seamless application.

The platform emerged from decades of experience building interactive solutions for Fortune 500 companies. The development team recognized that while enterprises collect vast amounts of data—with estimates suggesting 60-73% goes unused—the problem isn’t data scarcity but accessibility. Workers need information where and when decisions are made, not trapped in dashboards viewed back at a desk.

The Three-Mode Architecture

Virtual Reality: Third Spaces for Distributed Teams

opXR’s VR mode creates persistent virtual environments where distributed teams can gather, collaborate, and work productively regardless of physical location. Unlike video conferencing tools that simulate face-to-face meetings, these virtual spaces function as genuine work environments. A maintenance team spread across multiple facilities can meet in a shared virtual space to review procedures, examine 3D models of equipment, and conduct training sessions with spatial context impossible in traditional remote meetings.

The “FollowMe” feature enables instructors or subject matter experts to guide groups through virtual representations of facilities, pointing out specific equipment, procedures, or safety considerations. Trainees experience spatial learning—understanding not just what to do but where to do it—without traveling to physical locations. For global enterprises, this represents both cost savings and accelerated knowledge transfer.

Mixed Reality: Dynamic Digital Twins

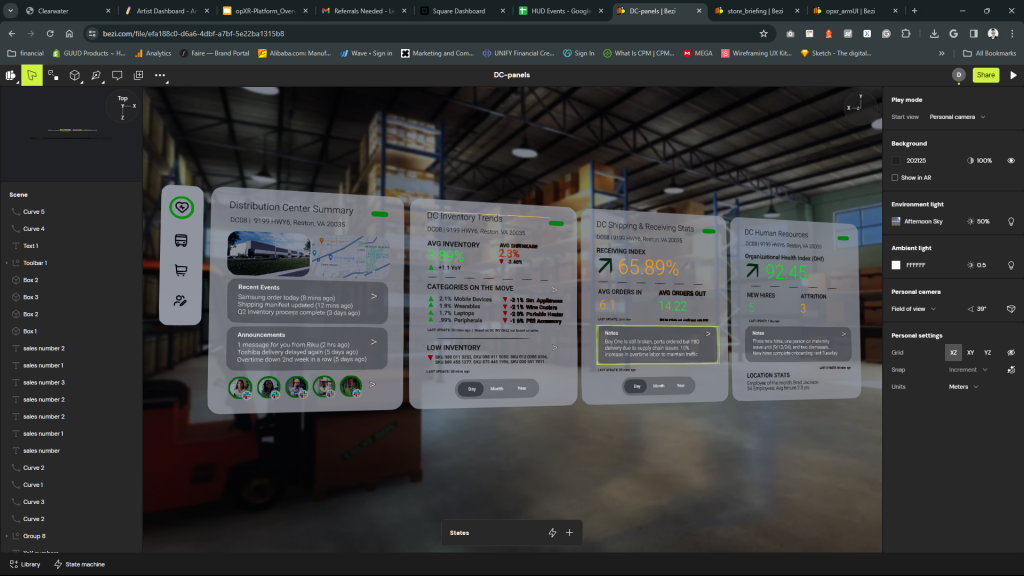

The mixed reality mode transforms opXR into what the team calls a “heads-up display for business.” On-site workers wearing Meta Quest 3 headsets see their physical environment augmented with live data streams, maintenance histories, sensor readings, and operational metrics. A technician looking at a piece of manufacturing equipment doesn’t just see the machine—they see its current status, recent maintenance records, performance metrics, and predictive maintenance alerts, all anchored to the physical object.

This dynamic digital twin approach pulls data from existing enterprise systems—ERP, manufacturing execution systems, warehouse management, enterprise asset management—and presents it contextually. The platform conducts discovery workshops with clients to map their technology stack and identify which data sources provide meaningful operational insights. Rather than requiring workers to remember which system contains which information, opXR aggregates and presents it where needed.

The code scanning feature exemplifies this integration. Workers can scan QR codes or equipment identifiers, instantly accessing comprehensive information about that asset: location in the supply chain, maintenance history, repair procedures, and real-time sensor data from connected IoT devices. Inventory counts that once required clipboards and spreadsheets happen in real-time, with data immediately syncing to warehouse management systems.

Augmented Reality: Standalone Productivity

For scenarios where full immersion isn’t appropriate, opXR’s AR mode provides a lighter-weight overlay of information onto the physical world. On-site teams access essential data and insights without removing themselves from their environment. This mode supports quick briefings, safety checks, and reference materials without the isolation of VR headsets.

Seamless Teleportation Between Modes

The platform’s defining feature is the ability to move fluidly between these modes within a single session. A remote expert can start in a virtual space, examining 3D models with a team, then “teleport” into a mixed reality view of the actual facility where an on-site technician is working. The remote expert sees what the technician sees, can markup objects in three-dimensional space, point out specific components, and guide troubleshooting in real-time. This Remote Assist functionality collapses geographic distance in ways that screen sharing never could.

Real-World Applications

Manufacturing: Boeing’s Assembly Complexity

Manufacturing environments showcase opXR’s capabilities most dramatically. Boeing uses extended reality to streamline complex assembly processes, and opXR’s approach extends this model. Engineers can conduct design reviews in VR, examining full-scale aircraft components without physical prototypes. When issues arise on the assembly floor, remote experts teleport into the mixed reality view of on-site workers, providing guidance overlaid directly onto the work environment. Maintenance procedures display step-by-step instructions anchored to the actual equipment being serviced.

Retail: Accelerated Training at Scale

For retail operations like Walmart, opXR transforms employee onboarding. New hires train in VR simulations of store environments, practicing customer interactions and inventory management in safe, controlled settings. Trainers can be physically located anywhere while guiding groups through virtual store layouts. When employees move to actual stores, the AR mode provides just-in-time reference materials—restocking procedures, promotional guidelines, equipment operation instructions—accessible on the floor without leaving customers.

Energy: Remote Inspection and Hazardous Environments

Energy companies operating offshore platforms or remote facilities face unique challenges. Shell and similar operators use XR for remote inspections, and opXR’s architecture specifically addresses these scenarios. On-site technicians in hazardous environments access real-time sensor data, equipment specifications, and expert guidance through mixed reality overlays. Remote teams monitor operations through dynamic digital twins, identifying potential issues before they become critical. Safety briefings and compliance training happen in VR environments that replicate dangerous scenarios without physical risk.

Technical Design Decisions

The Datafabric Layer

opXR’s architecture centers on what the team calls a “datafabric”—an integration layer connecting diverse enterprise systems. Rather than replacing existing infrastructure, the platform surfaces data from ERP, CRM, supply chain management, manufacturing execution systems, warehouse management, and business intelligence tools. This approach respects the reality that large enterprises have complex, entrenched technology stacks that won’t be replaced for a single application.

The datafabric also incorporates real-time feeds: security cameras, IoT sensors, weather data, traffic information. A facility manager in VR sees not just static building layouts but live occupancy data, environmental conditions, and equipment status.

Session Recording and Spatial Markup

The platform records user sessions, creating valuable training materials from actual work scenarios. A technician’s successful troubleshooting session becomes a reusable training module. Safety briefings capture spatial context—”stand here, watch for this”—in ways that written procedures or videos cannot convey.

Spatial markup tools allow users to annotate the three-dimensional environment. A remote expert circles a component, draws arrows, adds text notes, all anchored to specific locations in physical or virtual space. These annotations persist, creating institutional knowledge tied to actual places and objects.

Device-Agnostic Philosophy

While initially built for Meta Quest 3, opXR’s architecture emphasizes device agnosticism. The same virtual spaces, digital twins, and data integrations should be accessible across different XR hardware as the technology evolves. This forward-looking approach protects client investments in training content and operational workflows.

Addressing the Data Silo Problem

The platform directly confronts enterprise data silos—the fragmentation of information across incompatible systems. opXR doesn’t solve this by consolidating data but by providing a unified interface layer. Workers don’t need to know whether information lives in the ERP or the asset management system; they query opXR, which pulls from appropriate sources and presents integrated results.

This represents a shift from organizing data for storage to organizing it for access. The digital twin becomes the primary interface, with underlying systems functioning as data providers rather than distinct applications requiring separate logins and workflows.

opXR demonstrates how extended reality technology can address practical enterprise challenges rather than simply showcasing technical capabilities. By combining virtual third spaces, dynamic digital twins, and augmented reality overlays into a unified platform, it creates new modes of collaboration, training, and operational awareness. The ability to teleport seamlessly between remote and on-site perspectives, between virtual and physical environments, fundamentally changes how distributed teams work together on problems tied to specific places and physical assets. As enterprises continue grappling with hybrid work models and increasing operational complexity, platforms like opXR suggest how spatial computing might become as fundamental to business operations as email and video conferencing are today.

Please inquire for a demo.